Chemical etching mesh

Chemical etching mesh

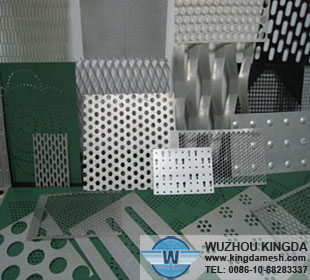

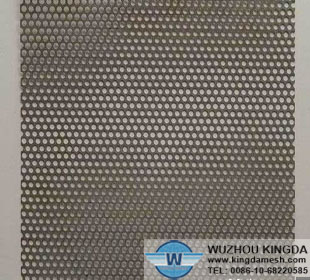

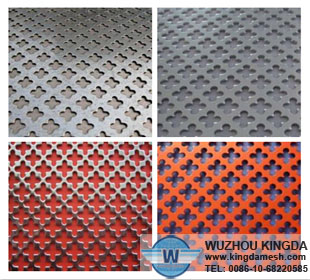

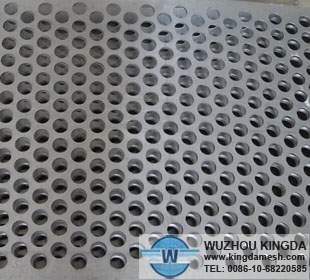

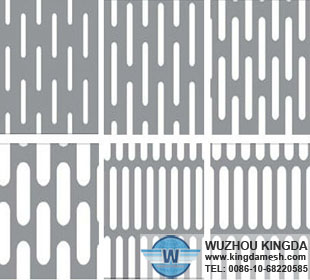

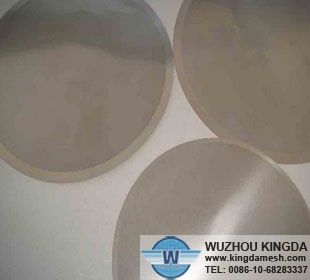

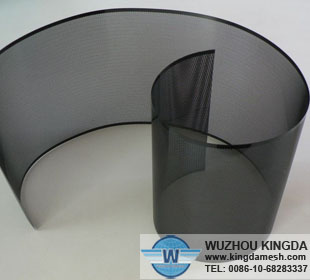

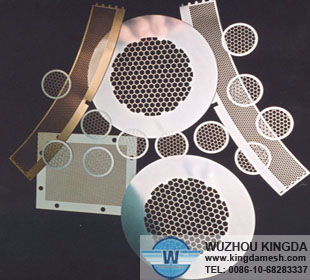

- Category:Perforated Metal Mesh

- Material:Stainless steel, copper, silicon steel plate, aluminum, nickel

- Properties:uniform sound abatement and attractive appearance

- Application:electronics industry, communication industry, automotive, medical, precision engineering, aerospace, military

tags:

Chemical etching mesh,etching mesh,

or

- Mesh Description

- Mesh Specification

- Relevant Picture

- Recommend Products

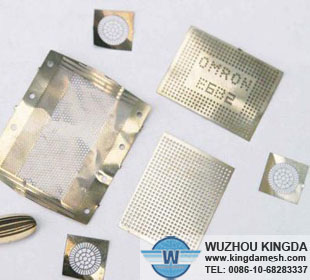

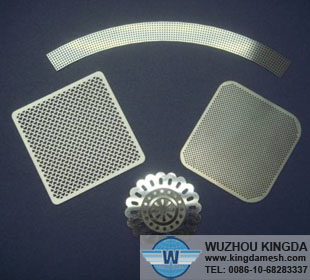

Chemical etching mesh

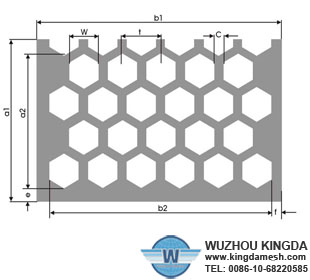

The specifications of Chemical etching mesh

1. The materials of Chemical etching mesh: Stainless steel, copper, silicon steel plate, aluminum, nickel, magnetic material and so on

2. Thickness: 0.03mm—1.5mm

3. Product size: 1*1mm—300*500mm

4. Smallest open hole: Ø0.1mm

5. Smallest line width: +/-0.025mm

6. Product precision: +/-0.01, it’s generally 20% of material thickness

The feature of Chemical etching mesh

1. Chemical etching mesh has uniform sound abatement and attractive appearance.

2. Chemical etching mesh is light weight and durable.

3. Chemical etching mesh has superior abrasion resistances and easy installation.

4. Chemical etching mesh is accuracy of size and can be readily formed.

The applications of Chemical etching mesh

1. Chemical etching mesh is used in electronics industry, communication industry, automotive, medical, precision engineering, aerospace, military, etc.

2. Chemical etching mesh is used for integrated circuit, screen printing electronic grille, precise filtration, microelectrode components, electronic industry plane pins, lead frame, substrate, etc. Chemical etching mesh is still can make signs, trademark and elegant handicraft.

3. Chemical etching mesh is mainly used in copier and printer accessories, electric screen grid, precision filter and Micro-electrode components, light transmitting plate.

If you are interested in our products, please feel free to contact us. TEL: 0086-10-68283337. Email: sales.wzjd@gmail.com

Related Products

Chemical etching mesh for filter

Chemical etching mesh for filter can be used in electronics, machinery

eched filtering mesh

eched filtering mesh is used for the petroleum& chemical Industry, foo

Etching screen filter

Etching screen filter is used for the petroleum& chemical Industry, fo