Stainless Steel Reverse Dutch Weave Filter Cloth

Stainless Steel Reverse Dutch Weave Filter Cloth

- Category:Stainless Steel Wire Mesh

- Material:stainless steel wire

- Properties:Woven Wire Mesh

- Application:widely used in filtering industry

tags:

Stainless Steel Reverse Dutch Weave Filter Cloth,Stainless Steel Dutch Weave Filter Cloth,

or

We highly appreciate your feedback. TEL: 0086-10-68220585 E-mail: sales@kingdamesh.com

- Mesh Description

- Mesh Specification

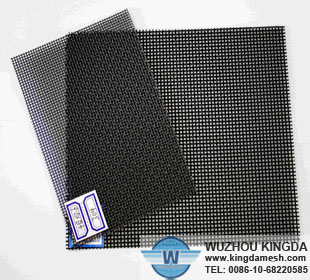

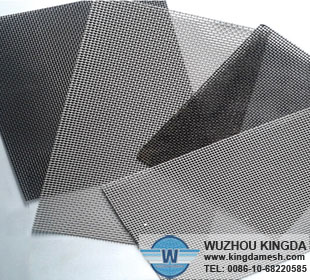

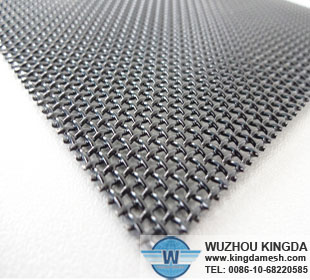

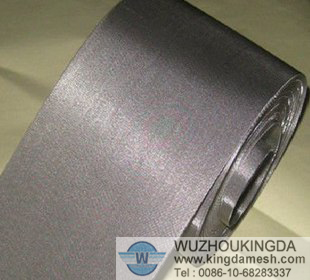

- Relevant Picture

- Recommend Products

Stainless Steel Reverse Dutch Weave Filter Cloth

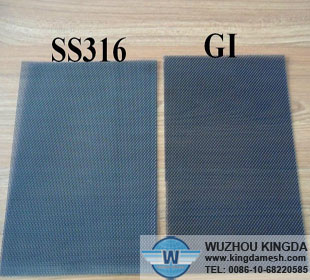

1. Material: AISI304, AISI316. The apparent difference of Reverse Dutch weaving compared with standard Dutch weave lies in the thicker warp wires and less weft wires. Reverse Dutch woven stainless steel wire cloth offers fine filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields

2. Type of weaving: Reverse Dutch weave

3. Stainless Steel Reverse Dutch Weave Filter Cloth Characteristics: Heat-resisting, acid-resisting, corrosion-resisting and wear-resisting

4. Performance characteristic:

4.1 The automatic instant mesh belt filters replace filter without any manual operation.

4.2 The material flow never fluctuates.

4.3 belt pumps make high quality, good stability.

4.4 No waste and less consumption of raw materials.

4.5 consist of 10 meters or 20 meters filter belt, belt box and electric control system.

4.6 Non-stop working production and absence of material fluctuation while exchanging screen.

5. Stainless Steel Reverse Dutch Weave Filter Cloth performance:

Wear-resistant, high strength, long life

Precise mesh, structural unity, not curly, easy to use

Screen thickness antistatic, anti-acid, corrosion

High temperature, pulling force and wear ability

With filter good precision, high load strength characteristics

6. Stainless Steel Reverse Dutch Weave Filter Cloth usage:

Widely used in aerospace, petroleum, chemical industry

Scientific research and transportation industries for acid and alkali under the conditions of screening or filtering environment

Petroleum industry make mud mesh, chemical fiber industry as screen filters

Electroplating industry for pickling mesh, printing mesh

Electronic battery industry and a variety of sophisticated filtration products.

1. Material: AISI304, AISI316. The apparent difference of Reverse Dutch weaving compared with standard Dutch weave lies in the thicker warp wires and less weft wires. Reverse Dutch woven stainless steel wire cloth offers fine filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields

2. Type of weaving: Reverse Dutch weave

3. Stainless Steel Reverse Dutch Weave Filter Cloth Characteristics: Heat-resisting, acid-resisting, corrosion-resisting and wear-resisting

4. Performance characteristic:

4.1 The automatic instant mesh belt filters replace filter without any manual operation.

4.2 The material flow never fluctuates.

4.3 belt pumps make high quality, good stability.

4.4 No waste and less consumption of raw materials.

4.5 consist of 10 meters or 20 meters filter belt, belt box and electric control system.

4.6 Non-stop working production and absence of material fluctuation while exchanging screen.

5. Stainless Steel Reverse Dutch Weave Filter Cloth performance:

Wear-resistant, high strength, long life

Precise mesh, structural unity, not curly, easy to use

Screen thickness antistatic, anti-acid, corrosion

High temperature, pulling force and wear ability

With filter good precision, high load strength characteristics

6. Stainless Steel Reverse Dutch Weave Filter Cloth usage:

Widely used in aerospace, petroleum, chemical industry

Scientific research and transportation industries for acid and alkali under the conditions of screening or filtering environment

Petroleum industry make mud mesh, chemical fiber industry as screen filters

Electroplating industry for pickling mesh, printing mesh

Electronic battery industry and a variety of sophisticated filtration products.