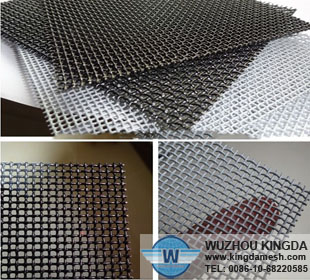

Stainless steel screens

Stainless steel screens

- Category:Stainless Steel Wire Mesh

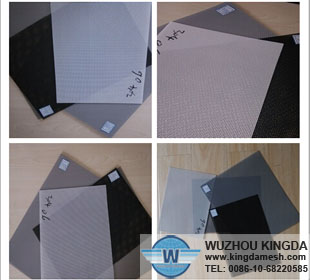

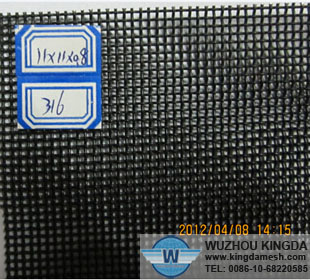

- Material:stainless steel Type 304, Type 304L, Type 316 and Type 316L

- Properties:Woven Wire Mesh

- Application:widely used in filtering industry

tags:

Stainless steel screens,Stainless Steel Mesh,Stainless screens,

or

We highly appreciate your feedback. TEL: 0086-10-68220585 E-mail: sales@kingdamesh.com

- Mesh Description

- Mesh Specification

- Relevant Picture

- Recommend Products

Stainless steel screens

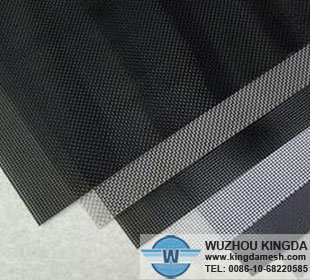

1. Materials: Wuzhou Kingda Stainless steel screens products are generally made of stainless steel Type 304, Type 304L, Type 316 and Type 316L.We produce wire cloth in all kinds of forms. The weaving is determined according to our customers, specific requirements, such as the material, the wire diameter, the size of the mesh, width and length.

2. Stainless steel screens offer a comprehensive range of products for a wide range of applications:

2.1 Flat top screens (EG))

Backing mesh for fine filter cloths offering a higher surface loading capability

2.2 Double crimped screens (GG)

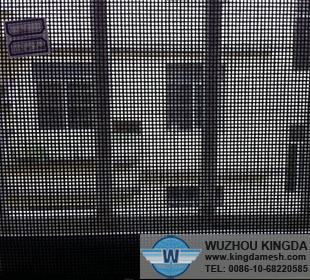

Sieving and sizing support screen for fine wire cloths and other filter media, enclosures, architectural applications

2.3 Special design

Coarse surface makes this screens ideal for use with husks and granules for the food industry, as well as decorative and design products and applications in interior design

2.4 Intermediate crimped screens (WG)

Interior design, backing mesh and profiling, protection against impact

3. Properties of Stainless steel screens:

3.1 Flat top screens (EG)

The top face of the screen is flat and therefore offers optimum supporting surface for the overlying mesh. The underside consists of offsets which will not impede the through flow of the filtrate.

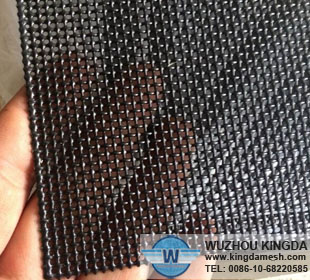

3.2 Double crimped screens (GG)

Double crimped screens are symmetrical in construction. The top faces and undersides are identically offset.

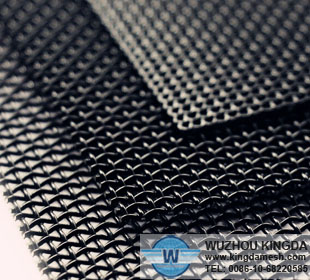

3.3 Special design

Double crimped screens with square wire in weft direction, round wire in warp direction

3.4 Intermediate crimped screens (WG)

There are more offsets used in this design to give greater stability to the backing mesh. However, only every third or fifth offset has a cross wire. This provides a greater number of support points for the overlying mesh, giving a more open sieving area.

1. Materials: Wuzhou Kingda Stainless steel screens products are generally made of stainless steel Type 304, Type 304L, Type 316 and Type 316L.We produce wire cloth in all kinds of forms. The weaving is determined according to our customers, specific requirements, such as the material, the wire diameter, the size of the mesh, width and length.

2. Stainless steel screens offer a comprehensive range of products for a wide range of applications:

2.1 Flat top screens (EG))

Backing mesh for fine filter cloths offering a higher surface loading capability

2.2 Double crimped screens (GG)

Sieving and sizing support screen for fine wire cloths and other filter media, enclosures, architectural applications

2.3 Special design

Coarse surface makes this screens ideal for use with husks and granules for the food industry, as well as decorative and design products and applications in interior design

2.4 Intermediate crimped screens (WG)

Interior design, backing mesh and profiling, protection against impact

3. Properties of Stainless steel screens:

3.1 Flat top screens (EG)

The top face of the screen is flat and therefore offers optimum supporting surface for the overlying mesh. The underside consists of offsets which will not impede the through flow of the filtrate.

3.2 Double crimped screens (GG)

Double crimped screens are symmetrical in construction. The top faces and undersides are identically offset.

3.3 Special design

Double crimped screens with square wire in weft direction, round wire in warp direction

3.4 Intermediate crimped screens (WG)

There are more offsets used in this design to give greater stability to the backing mesh. However, only every third or fifth offset has a cross wire. This provides a greater number of support points for the overlying mesh, giving a more open sieving area.

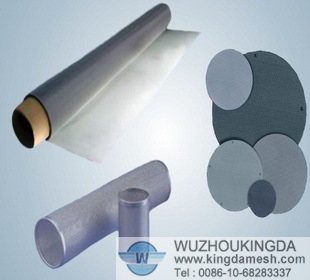

Related Products

Stainless steel screens

Features of stainless steel screens are corrosion resistant, acid resi

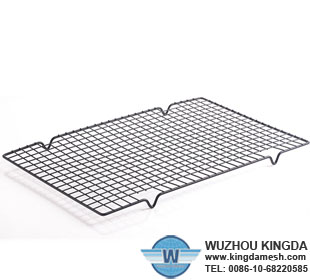

Stainless steel mesh racks

Stainless steel mesh racks have great Surface for cooling cookies, cak

Stainless steel mesh trays

Stainless steel mesh trays are mainly used as a cleaning basket, fruit