Weaving Methods of Stainless Steel Wire Mesh

Weaving Methods of Stainless Steel Wire Mesh

1. Plain Weaving

The plain weaving is the most commonly used and simplest wire mesh weave. Each warp wire (wire running-parallel to length of cloth) passes alternately over and under the wires running traversely through the cloth at 90 degree angles. It has an extremely wide range of applications. Plain weave stainless steel wire mesh offers high filtering efficiency, low pressure loss, constant mesh opening, good dimensional stability, high open surface area and good fireproof property.

2. Dutch Weaving

The dutch weave is produced by the use of coarse mesh in the warp and a fine mesh with relatively smaller wire in the fill. This weave results in greater strength with very fine openings and is primarily used as a filter cloth. The shape and position of the openings aid particle retention.

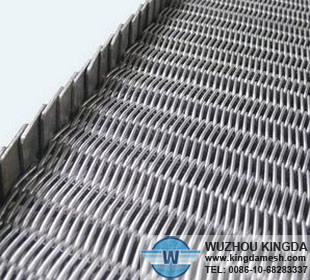

3. Twilled Weaving

The twilled weaving is produced by passing each fill wire alternately over and under two warp wires. The pattern is staggered on successive warp wires, giving the appearance of parallel diagonal lines. This weave allows the use of proportionately heavier wires in a particular mesh count than is possible in plain weave.

4. Twilled Dutch Weaving

Twilled dutch weaving stainless steel wire mesh is produced by a combination of the features of the dutch weave and twilled weave. Fill wires are passed alternately over and under two warp wires forming a fine mesh in one direction and a coarse mesh in the other. This type of weave is capable of supporting greater loads than the dutch weave, with finer openings than the twilled weave. It packs even more wires in a given area than dutch plain woven wire cloth. Generally, twilled dutch weave stainless steel wire mesh offers finer mesh counts and lower flow than other dutch woven wire cloth and can be made to filter particles as fine as 2 microns in diameter.