Perforated metal panels are increasing in popularity

Perforated metal panels are increasing in popularity as a functional fit for balustrading. Many Architects now choose perforated metal as they offer a safe and low maintenance solution for a façade. Perforated metal also enables you to give your building its own unique character.

The question is which pattern of perforated metal should you choose – which pattern will enhance the building’s style, satisfy the legislation and be cost effective?

The choice of perforated metal patterns is literally infinite and Bion, as a bespoke perforator, will work with you to get the right pattern for you.

The key pattern choices are:

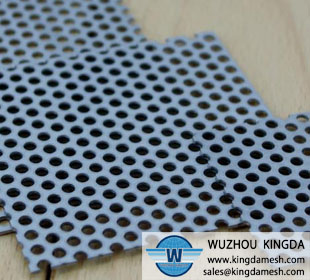

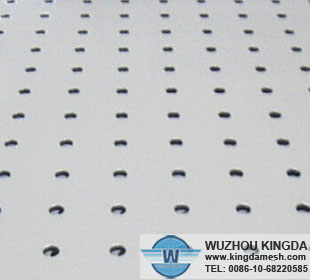

Hole Type: With many standard patterns the choice is limitless. We will advise if the sheet thickness to hole size ratio is achievable using the perforation process.

Hole size: 200mm, 100mm, 3mm diameter large feature holes to make a statement or tightly spaced small holes to create a semi-transparent window.

Prforated metal pattern Layout: How about a bespoke perforation which shows your own logo made from holes. Or a cost effective standard 60 degree pattern. Bion look to work in partnership so please use us to work alongside your design team to create the perfect perforation for you.

What about cost:

What are the cost implications of your choice of pattern? Processing cost can be higher if the pitch of the pattern is small. We have a wide range of standard patterns which require no additional tooling costs. However up front tooling investment can drop processing times and make the overall project cost less. Bion’s Technical brochure has a number of standard patterns which can help you make your choice.

- Prev : Uses for Expanded Metal

- Next:No Article